Polymer coating controlled-release technology

The most reliable and effective way to control the availability of nutrients for plant uptake is by regulating their release into the soil solution. This is achieved by encapsulating solid fertilizer particles in a polymeric coating.

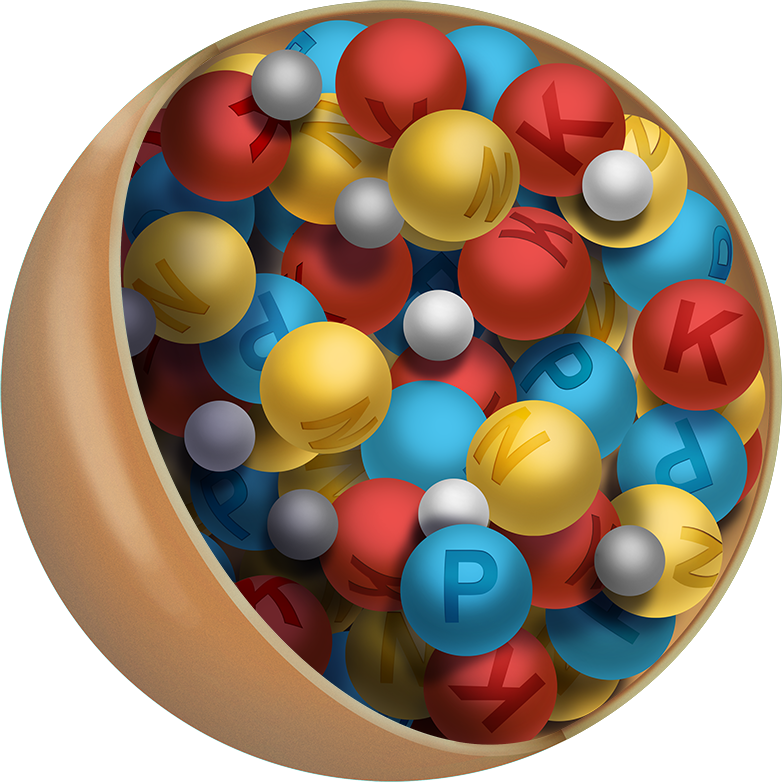

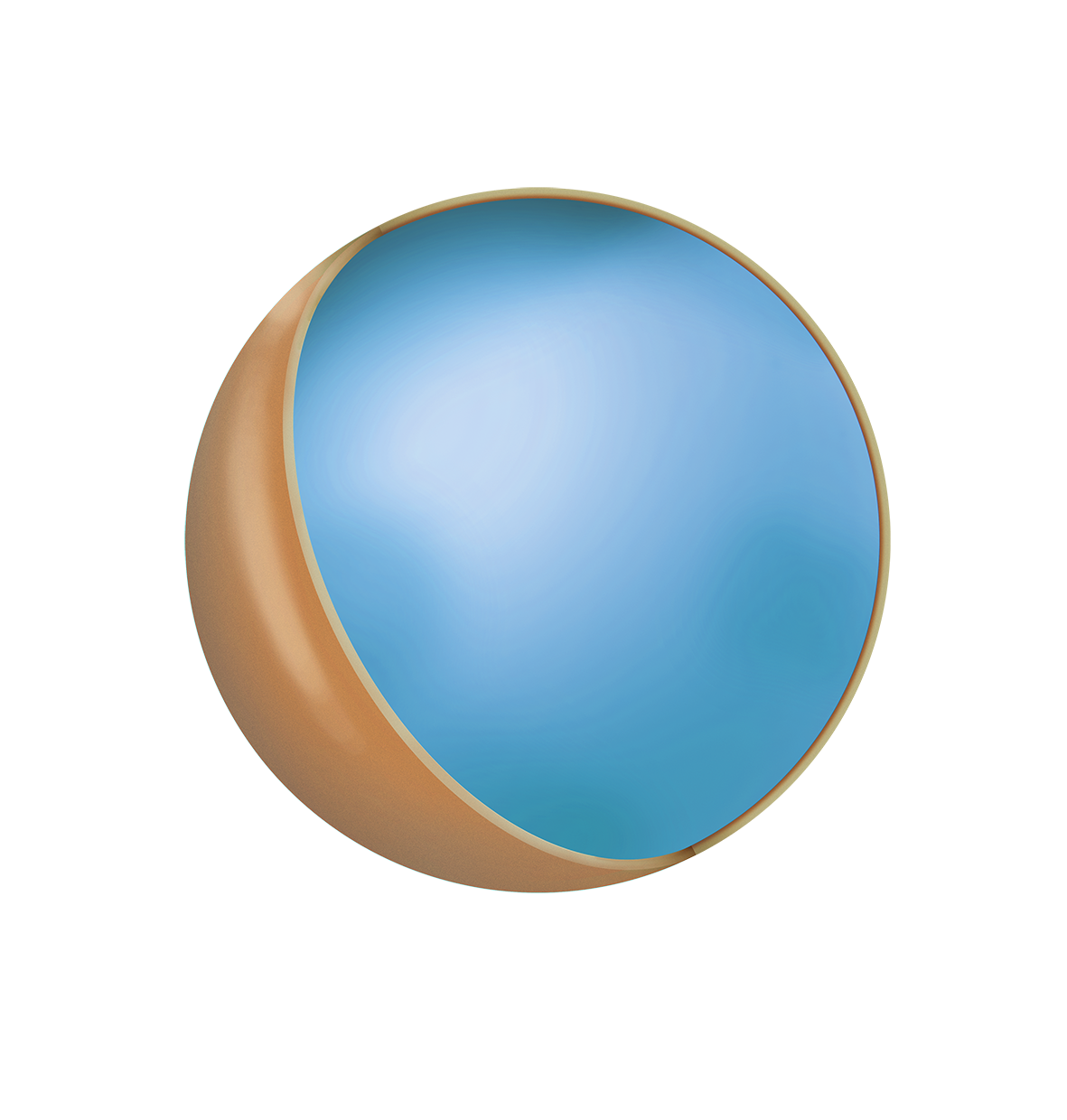

During the production process, granules of soluble fertilizer are coated with very fine polymer layers. This polymer coating, which acts as a semi-permeable barrier, allows measured diffusion of nutrients when the fertilizer granules are applied to the soil.

| Multicote™ products are based on polymer-coated fertilizer granules. During the production process, water-soluble nutrients are encapsulated in a polymeric shell. |

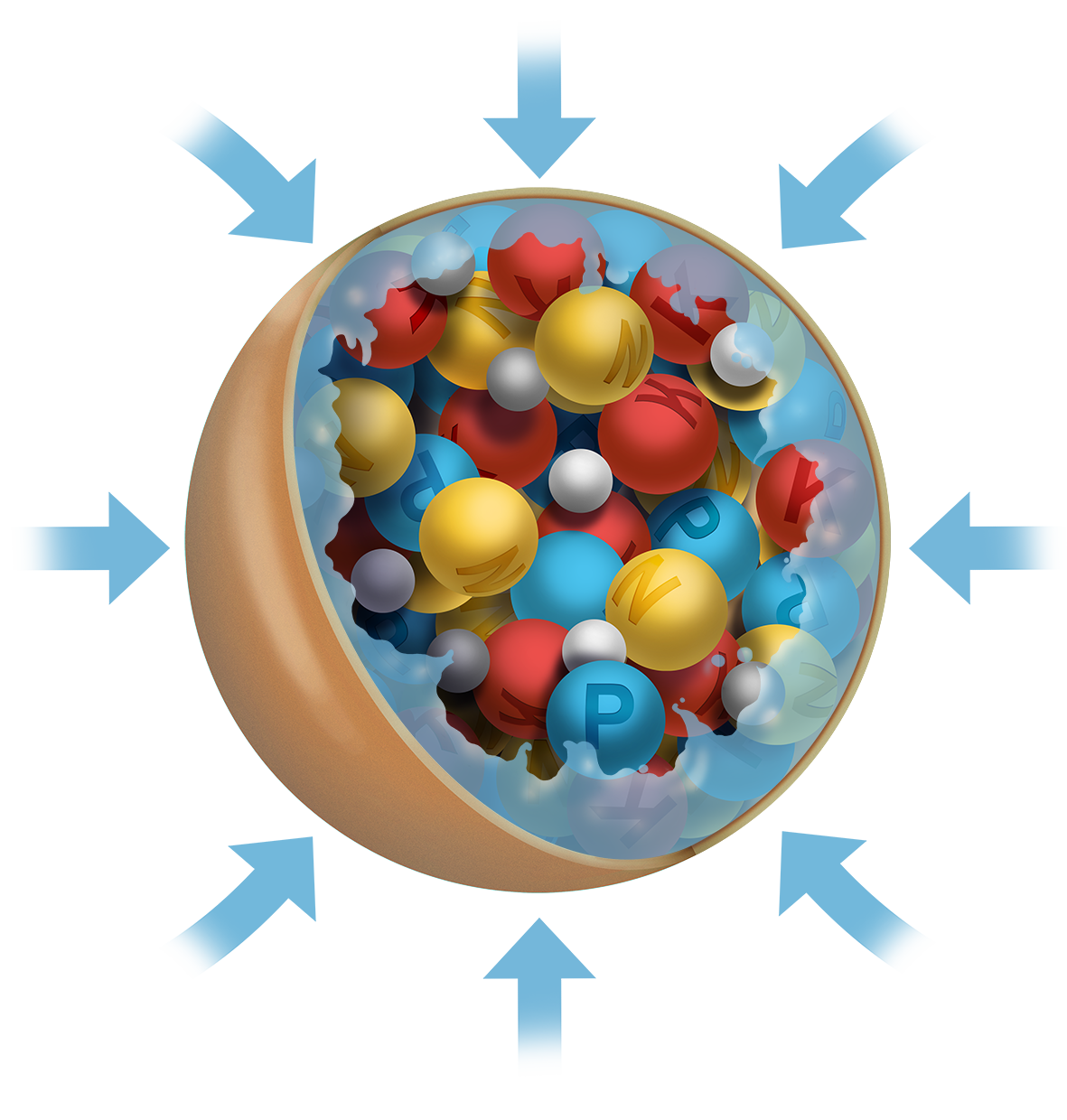

| Following application, soil moisture slowly penetrates through the coating. This moisture starts a gradual dissolution of the nutrients inside the granule. |

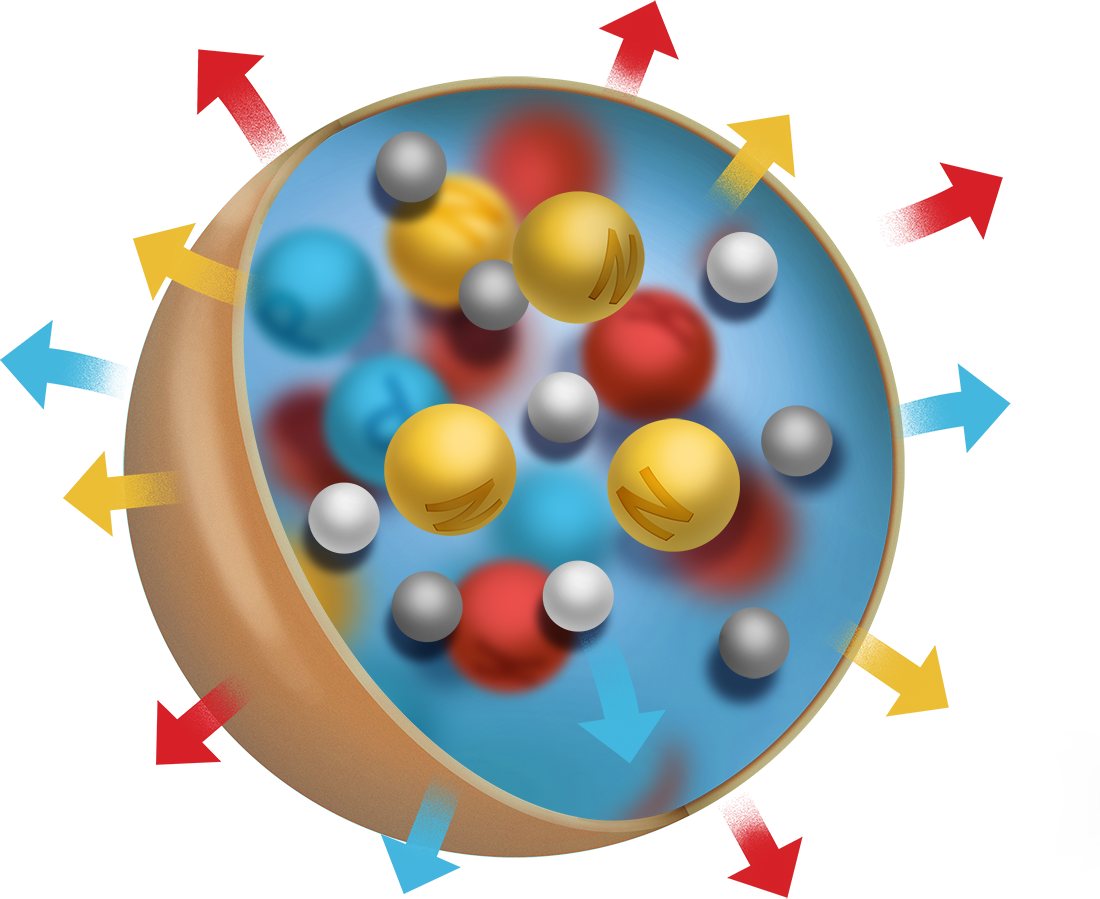

| The dissolved nutrients diffuse through the coating to the root zone, providing the plant with available nutrients at measured portions – according to its growth needs. The rate of diffusion – the actual release rate depends upon and is dictated solely by the soil temperature. The release rate increases as temperature rises, just as happens with plant uptake rates. The release rate during this phase is constant, given sufficient moisture for plant growth and subject to soil temperature fluctuations only. |

| While nutrients are released to the root zone, further penetration of moisture dissolves more of the solid fertilizer.At a certain stage, the entire content of the granule is dissolved, ready for diffusion and release. From this stage the release rate slows down. |

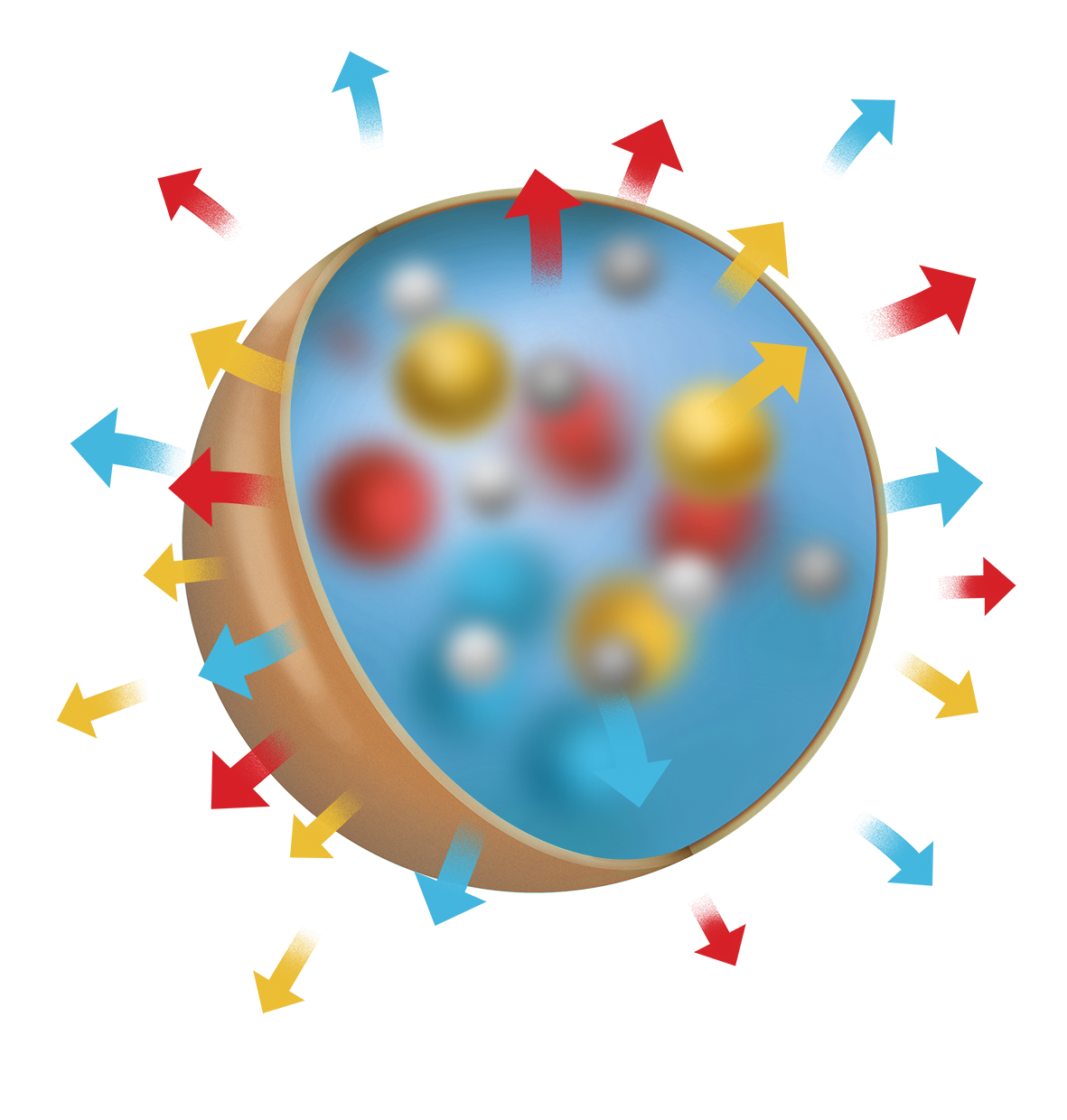

| After the release is complete, the empty shell ruptures and degrades, leaving no residues in the soil. |